Lights-out is a manufacturing methodology in which manufacturing is fully automated and requires no human presence so that the lights and even ventilation can be shut off. While the concept sounds futuristic, it has been circulating around for a couple of decades now. In fact, several organizations have operated some form of lights-out factories throughout the past few decades

IBM built a lights-out plant in Texas in 1980 to assemble computer keyboards. However, the project was shut down because of the fixed tooling, which made the plant inflexible to adapt to product variations. Similarly, GE operated a light bulb factory in Virginia from the early 1990s, which produced more than 10,000 units per hour with only a few human workers assigned to perform maintenance of the machines before the factory was shut down in 2010. Looking at more successful cases, Fanuc has been running 22 lights-out factories since the early 2000s that use robots to manufacture CNC machines. The robots can go unsupervised and without maintenance for as long as a month at a time. Similarly, in the Netherlands, Philips has been running lights-out manufacturing plants to produce electric razors with a team of 128 robots and nine quality assurance (QA) workers.

It’s clear that lights-out isn’t a new concept, but it has been gaining strong momentum in the past few years for various reasons. On the other hand, despite the driving forces, there are still barriers to adoption. In this blog, we discuss the types and significance of the drivers and barriers for lights-out.

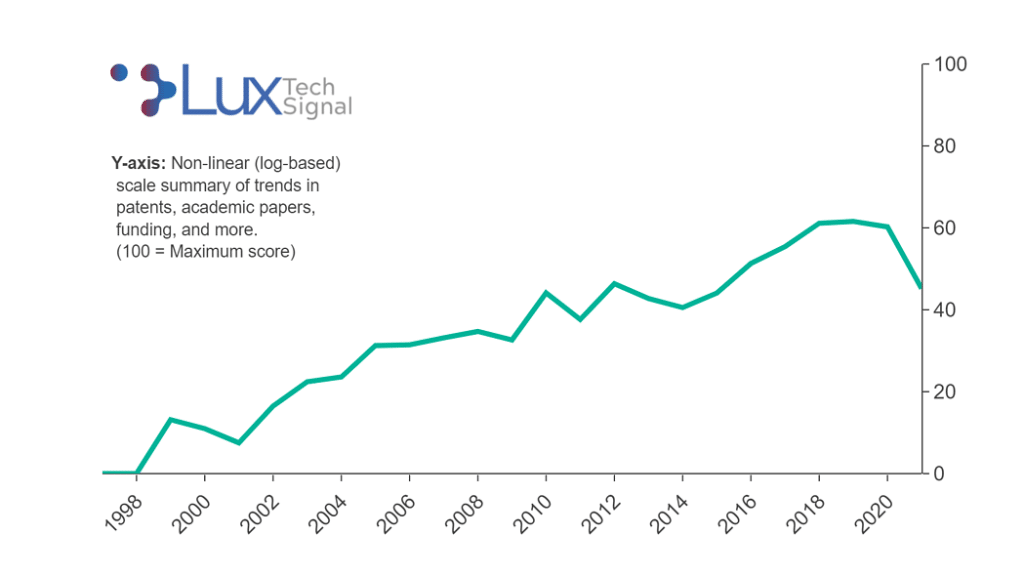

Lux Tech Signal

Using the Lux Tech Signal graph, we can see that there is steadily increasing activity in lights-out manufacturing. Some of the ideas developed in the late 20th century are getting enabled by modern technologies like advanced robotics, computer vision, industrial IoT, machine learning algorithms, and improved computing (cloud and edge). Besides technical enablement, there are other factors responsible for the growing demand for lights-out, which we’ve listed below.

Drivers for Lights-Out:

1. Minimizing operational cost

One of the motivations for automation is to reduce operational costs. While robots have high upfront costs, they can be less expensive than human labor over time. In addition, the push to increase minimum wages and benefits for factory workers is driving large corporates toward increased levels of automation.

2. Achieving higher efficiency using automation

Unlike human workers, a robustly built robotic system can run 24/7 without the need for breaks, vacations, and shift changes. This higher throughput can make automated robots more efficient than human workers.

3. Reducing downtime

Some estimate that around 23% of all unplanned downtime in manufacturing is caused by human errors. These can lead to millions of dollars in lost revenue, depending on the nature of the production facility. In addition to the unplanned downtime, the lack of flexible production systems and the need for manual inspection, maintenance, and repair (IMR) are reasons for planned downtime in manufacturing. Companies are keenly interested in automating these tasks and processes to reduce downtime.

4. Minimizing wastage for sustainability reasons

In addition to operational and maintenance costs, inefficiency and downtime caused by human workers and inflexible manufacturing systems also lead to increased material wastage and carbon footprint. For example, Siem Offshore has partnered with a predictive maintenance (PdM) vendor to reduce its carbon footprint caused by traveling crews for IMR. Similarly, Canadian company Eigen Innovations claims to reduce material waste from industrial processes using its automated inspection system. The growing megatrend of reducing carbon emissions will further drive the requirement for automation.

5. Rising worker safety concerns and associated costs

Utilizing technologies to improve worker safety has proven to be a double-edged sword for factory workers. A safe workplace for factory workers has several advantages, but it comes at an increased cost, which large organizations are already trying to trim. While replacing some workers with robots can help save operational costs, the use of collaborative robots (cobots) requires further worker safety measures for the remaining workers. Therefore, companies are interested in full automation with lights-out.

6. Labor shortages

Some industries, such as oil and gas, have been notoriously suffering from labor shortages caused by both aging workplaces and the lack of fresh graduates in the field. Even for other industries, knowledge transfer and worker training for new hires are difficult and expensive, making this a growing reason for the need for automation.

7. Product customization

There is an increasing need for customized products and packaging in almost every industry. However, meeting this demand is difficult even for companies that are advanced in digital transformation and use robots to manufacture and assemble parts in siloed environments. The optimal use of resources and flexible manufacturing processes required to manufacture custom products based on demand can be achieved using holistic automation of multilevel processes (see Siemens case study). A fully automated factory ideally solves this by unifying automation from factory-level management systems to computer-controlled machines.

8. COVID-19

The COVID-19 pandemic has been an unprecedented driver for several tech innovations (see our report), including lights-out. It has made companies realize the importance of automation, as many factories had to shut down due to workers’ unavailability caused by sickness and regulations. Companies like Hitachi, Mitutoyo, and Omron have also used COVID-19 as a motivation for their investments and M&A initiatives in automation since 2020.

Barriers to Automation:

1. Technology bottlenecks

While there have been ongoing developments in smart manufacturing, the technologies required for full automation or lights-out still lag behind the demand. In addition to bottlenecks in sensing, connectivity, and real-time feedback and processing, there is also a lack of uniform standards for automation in the manufacturing industry. This is such a significant barrier for automation that some organizations have taken steps back from lights-out. In his famous “humans are underrated” tweet, Elon Musk apologized for using “excessive automation” at Tesla and replaced robots back with human workers. Tesla later revealed that replacing automation with good old-fashioned human workers fixed some quality-related problems in its vehicles.

2. Financial feasibility

Although robots might be less expensive in the long run, their excessively high cost often becomes a barrier to adoption, especially for small manufacturing companies. In addition, using robots is still more expensive for countries with low human labor costs and lax worker safety regulations.

3. Regulatory hurdles and cultural pushback

Automation is often criticized, as it can take away jobs and poses the threat of causing more widespread unemployment. While lights-out may be a utopian future for companies because of the advantages of automation we discussed above, it is also a dystopian concept for people who support workers’ rights and, therefore, have demanded regulations against such large-scale automation. Although people’s perspectives on automation and lights-out differ based on different countries, cultures, and political views, it is certainly a substantial barrier.

4. Skill gaps

While lights-out might put tens of thousands of factory workers out of work, it will also create a demand for a new type of workforce that designs and develops the necessary hardware and software for these systems. This will add to the already-existing talent shortage in the skilled workforce, especially in data analytics.

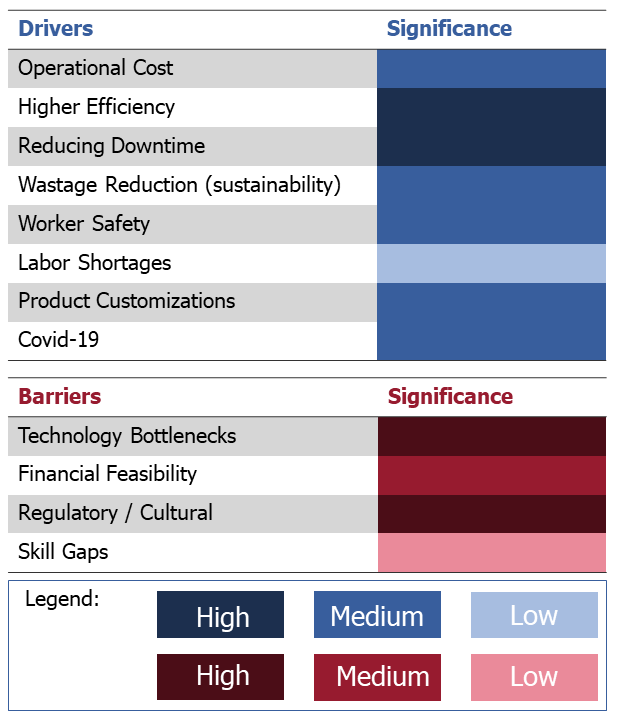

Visualization of Drivers and Barriers of Automation

#LuxTake:

- While the drivers for automation are growing at an increasing rate, there are still several barriers to its adoption. The balance between drivers and barriers will define the timeline of lights-out.

- As machines are more efficient and less erroneous than humans, the most significant drivers for automation are higher production efficiency and downtime reduction.

- On the other hand, the most significant barriers to automation are technology bottlenecks and regulatory/cultural issues. While automation technologies will continue to mature over time, organizations will also need to implement a strategic shift in company culture for acceptance of automation at all levels.

- There is not a switch to instantly implement lights-out; it’s a multistep process. The timeline for full automation also depends on the digital maturity of your business, which clients can assess using the framework in our report.